In the manufacturing and assembly industry, Takt Time, Cycle Time, and Lead Time are some of the fundamental concepts that help managers to better understand how to optimize workflow, resources, and the time it takes to complete a project. These three lean manufacturing processes can be confusing to a lot of practitioners in the field of project management. In today’s post, we demystify the difference between Lead Time, Cycle Time, and Takt Time, highlight their relevance, and also outline the calculation methods for each of the times.

What Is Takt Time?

Takt Time is the pace of production in a company. That is the rate at which a company needs to produce a product to meet the customer’s needs. Put another way, Takt Time is the maximum acceptable time to meet the customer’s demands.

Takt is a German word for heartbeat or pulse. And just the same way your heart rate speeds up or slows down depending on your body activity, Takt Time can also fluctuate, affecting your production process.

Takt Time is based on customer demand, and by understanding it, you can meet your customers’ needs. By establishing a consistent production system, you can ensure that the available minutes are properly utilized to give consumers the right quality of products at the right time.

Benefits of Takt Time

Integrating the use of Takt Time into your production processes will have the following benefits:

- You will be able to meet actual customer demand, thereby eliminating the time wasted on overproduction.

- Takt Time helps you develop a standardized workflow that promotes quality and efficiency.

- Takt Time enables you to set real-time targets for production where operators know exactly what their work output should be like at any given time.

- You will be able to establish and achieve a steady and continuous flow of production.

- Takt Time enables you to reduce errors, minimize overtime, and estimate service delivery processes.

- Takt Time helps you determine your company’s efficiency.

How to Calculate Takt Time

Takt Time is used to align production to customer demands. When you produce faster than Takt Time, it will result in overproduction. On the other hand, if you produce slower than Takt Time, the customer’s demands will not be fulfilled on time. Takt Time cannot be measured using a stopwatch but rather must be calculated based on customer demand.

The Takt Time formula is as follows:

Takt Time = Net Production Time (NPT) / Customer Demand

Net Production Time describes the clean time your production team has at their disposal to complete the production process. It includes only the time your team will be actively working to create value for your customers. That means you must exclude downtime, including meetings, tea and lunch breaks, scheduled maintenance, shift changeovers, etc.

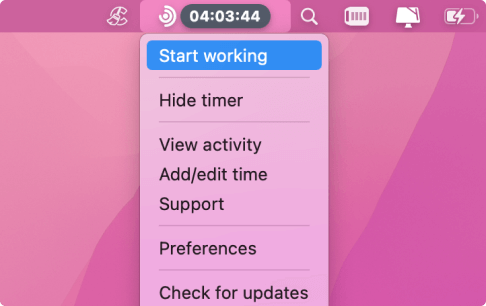

To make the process smooth, we recommend using a time tracking solution like Traqq to track and record your team’s total ‘available’ or production time – that is, the time your team spends on producing an item. Traqq also lets you track downtime, making it easy to separate it from the Net Production Time. This way, you can find loopholes in the entire process and eliminate time wastage.

Customer Demand, on the other hand, describes the number of units/products your customers purchase regularly (usually daily). For a company producing a single product, the formula is pretty simple. However, it can be quite complicated if your company manufactures a variety of products, each with its own customer demand.

Consider the example below:

Let’s say you run a company that sells burgers. Suppose the daily customer demand is 300 pieces, and you have 500 minutes per day to make these burgers. You take two tea breaks of 15 minutes each and a 30-minute lunch break.

Your Net Production Time = Total working minutes – Total non-working minutes (tea and lunch breaks). That amounts to 500 – 60 = 440 minutes.

Now, your customers demand 300 pieces each day.

So, your Takt Time = NPT / Customer Demand = 440 / 300 = 1.46

Therefore, we can conclude that if you produce one burger every 1.46 minutes, your production will be aligned with your customers’ demands.

What Is Cycle Time?

Cycle Time describes the time your team spends on the production of an item, up until the item is ready for delivery or shipment. Put simply, Cycle Time starts when the manufacturing process of one unit starts and lasts until it ends.

A better way to understand this concept is to look at the relationship between Cycle Time, Throughput Time, and production rate. Throughput Time describes the number of units you can manufacture during a given time period. In line with that, Cycle Time is the average amount of time your team will need to produce one item.

From the example above, it takes you 500 minutes to produce 300 burgers, making 300 units per 500 minutes your Throughput Time. Therefore, we can conclude that it takes you 1.66 minutes to produce one burger, meaning 1.66 minutes per product is your Cycle Time.

Benefits of Cycle Time

- It enables you to understand the variations of production.

- It gives you insight into how to pace the production rate to satisfy customer demand.

- It helps you to decide the actual delivery time.

How to Calculate Cycle Time

Since Cycle Time is the amount of time you spend producing one product, you must include all the hours in your Net Production Time. The Cycle Time formula, therefore, is as follows:

Cycle Time = Net Production Time / Number of Units Produced

From our burger business above, let’s assume we use the same Net Production Time of 500 minutes. But this time, we’ll only make 250 burgers.

Here’s how to calculate the Cycle Time:

Net Production = 500 minutes

Number of Burgers Made = 250 burgers

Daily Customer Demand = 300

Cycle Time = Net Production / Customer Demand = 500/250

Therefore, Cycle Time is 2 minutes per burger.

Takt Time vs. Cycle Time

So, what’s the difference between Takt Time and Cycle Time?

Whereas Takt Time refers to how often a unit must be produced to meet customer demand, Cycle Time is the actual time it takes to produce the same unit.

Considering that your Cycle Time is longer than your Takt Time, we can tell that you are running a few seconds (0.54 seconds) behind in the production of each unit. That accumulates to approximately 4.32 minutes each day. In other words, you are falling short of your customer demand by approximately 3 burgers every day.

On the other hand, if your Cycle Time is shorter than your Takt Time, you may be overproducing burgers, thus exceeding your customer demand. Ideally, your Takt Time and Cycle Time should be equal.

To sync the Cycle Time and Takt Time, you may need to make some adjustments to your workflow. Using time tracking software will help you identify time wastage and allocate that time to the production process. You will also be able to identify workers who waste a lot of time on non-work-related staff and implement ways to improve their performance and efficiency.

What Is Lead Time?

Lead Time covers the entire production process, from the moment you take an order to the time you deliver the item and receive payment. Unlike Takt Time and Cycle Time, which are related to production only, Lead Time depicts the entire journey of the product.

Let’s say a customer calls in to place an order for four burgers. You receive the order at 9 AM and deliver it at 1 PM. The Lead Time here is four hours.

Consider another example where a client places an order for customized T-shirts. The order is placed on June 14, and your team starts working on it on June 15. The entire process takes your team four days, so June 19 is the day you complete the production process. You ship the T-shirts, and it takes them two days to be delivered to the client – so June 21 is the day your customer receives the T-shirts. After confirming the entire order, your customer takes two days to pay for them, so June 23 is the day you receive payment.

From this example, the Lead Time will be 9 days.

The Lead Time formula is below:

Lead Time = Pre-processing time + Processing time + Post-processing time

Cycle Time vs. Lead Time

As touched on earlier, Lead Time shows the entire manufacturing process of your company, including Cycle Time. While Cycle Time only comprises the time from when manufacturing is started to the time it ends, Lead Time follows the unit from the first instance when the order was placed to the time the customer receives the product and makes payment.

Wrapping Up

All these three concepts – Takt Time, Cycle Time, and Lead Time – measure time in your manufacturing process. To be more efficient, you must find ways to speed up the production processes to meet customer demands and expectations.

By using a time tracker like Traqq, you can easily monitor employee performance, manage time spent on working and taking breaks, create reports, and analyze the productivity levels of each employee. With Traqq, every single minute is accounted for, thanks to the polite notifications that remind employees to start the timer if they forget to activate it.

With all the hours tracked, the application makes it easy to calculate the billable hours. Plus, payroll processing is automated, making payments accurate, swift, and seamless.

Find where your time goes. Start tracking time with Traqq today.