In 1913, Henry Ford established the first moving assembly line, which shortened the production of an entire car from over 12 hours to one hour and 33 minutes. This was a business process improvement that has brought innovation across various industries.

However, just because it worked for Ford, it doesn’t mean that you’ll use the same technique for your business. Every operation requires a business process improvement strategy that suits its specific needs. If you want to know the right way to streamline your company’s workflow and boost productivity, this article will show you everything you need to learn.

What Is Business Process Improvement?

Any task related to work is considered a business process. Whether you’re using a work time tracker, attending a weekly meeting, or creating a report, you’re engaging in a business process. Generally, it involves any project or organizational activity that will bring everyone closer to their goals.

The steps in a business process will depend on its level of complexity. However, it usually involves three to four aspects:

- Operations: This aspect consists of organizing and planning project resources, coming up with a feasible budget, and establishing clear objectives. It generally involves any business activity that determines a project or product outcome.

- Management: This aspect involves the actual execution of business plans and tasks.

- Support: This phase provides aid to the management aspect.

- Readjustment: This includes tracking risks, performance metrics, and opportunities to make appropriate changes that will perfect the end product.

Now, business process improvement involves documenting, analyzing, identifying, and enhancing functioning procedures to significantly transform your organization. Its ultimate objective is to improve your product’s quality and boost user experience. As a result, you can help your business grow. This experience is core, especially in the mobile-centric reality which is why businesses use the best embedded analytics tools to understand user behavior and improve it.

Business Processes Improvement Importance

Improving business processes is crucial for organizations looking to enhance efficiency, reduce costs, and gain a competitive edge. Here is a list of the importance of business process improvement factors:

- Increased Efficiency: Streamlined processes reduce wasted time and resources, enabling the organization to operate more smoothly and efficiently.

- Cost Reduction: Improved processes often lead to significant cost savings by eliminating unnecessary steps and optimizing resource use. 3.

- Enhanced Quality: By improving business processes, organizations can reduce errors and improve the quality of their products or services, leading to higher customer satisfaction.

- Agility and Flexibility: Well-optimized processes enable organizations to respond more quickly to market changes, emerging opportunities, and competitive pressures. 7.

7 Business Process Improvement Methodologies

Applying the changes you need will be easier if you properly choose the ideal business process improvement methodology. With the right tool, mapping the plan will be simpler for the entire team. Here are the best and most popular methodologies for improving business processes:

1. Six Sigma or Lean Six Sigma

Introduced by former Motorola engineer Bill Smith in 1986, Six Sigma reduces the probability of errors to 3.4 defects per million occasions. In theory, this approach leads to stability or increased process repeatability.

This methodology requires advanced knowledge in statistics, and it was designed for the manufacturing industry. If you’re taking this approach, you’ll need to work with a certified Six Sigma consultant or specialist.

2. Lean Management

Also known as “The Toyota Way,” Lean Management is a production method that promotes continuous improvement and employee respect. According to automotive industry researchers James Womack and Daniel Jones, there are five Lean Principles:

- Specify Value – The ultimate customer is the only one who can define “value”.

- Identify the Value Stream – This includes all the necessary actions for bringing the product to the customer.

- Flow – Ensure that value-generating steps flow.

- Pull – The customer must pull the product from you.

- Pursue Perfection – The process of reducing costs, time, space, and mistakes is never-ending.

3. Agile Management

Popularly used in the IT industry, Agile Management allows you to break the projects into different parts:

- Designing

- Developing

- Testing

- Improving

This approach promotes making improvements within a particular life cycle and not after it ends. Note that Agile Management is not ideal for startup businesses. This methodology focuses more on redefining an organization’s work culture.

4. Total Quality Management (TQM)

Total Quality Management promotes taking a simple approach to business process improvement. It requires everyone’s involvement in continuously elevating quality. What’s more, its goal is to achieve customer satisfaction by creating a better product or experience for your clients. It’s worth noting that this methodology is integrated into the company culture to ensure that all processes are balanced and coherent.

5. Kaizen

Kaizen is a Japanese business philosophy that translates as “continuous improvement” or “change for the better” in English. The Six Sigma methodology was based on this approach, but you can use it separately.

It promotes a healthy, stable, and friendly work environment. As a result, employees are engaged, motivated, and comfortable. Of course, this also leads to a boost in productivity.

6. Cause and Effect Analysis

More popularly known as the “Fishbone Diagram,” Cause and Effect Analysis helps you visualize the root sources of a problem. When you take this approach, you need to assemble a team and brainstorm ideas. Doing so should help you find the causes of a particular issue.

7. Kanban

Created in the 1940s in Toyota factories, Kanban is a methodology that uses a visual system of To-Do, In Progress, and Completed cards. Also known as the “Just-in-Time (JIT) system,” this approach optimizes work while delivering quality results promptly. There are also several online tools that use this methodology. Some of the popular programs include Trello, Asana, Monday.com, and ProofHub.

7 Business Improvement Strategies

Business process improvement strategies can lessen errors and delays while improving customer satisfaction. Now, where do you begin? Here are 7 business process improvement steps you can take to enhance your business process, cut waste, and boost efficiency.

Step 1: Identify What You Need to Change

The first thing you need to do is conduct a thorough analysis of your business process to identify what you need to change. Your audit will help you discover hidden risks and issues.

Step 2: Assess Challenges

Once you’ve identified which aspects of your process you need to improve, you need to conduct an analysis. You must understand the situation to make practical and realistic improvement plans. You need to ask the following questions:

- Which steps are generating hindrances?

- Which parts are taking so much time?

- What are the expected increases in cost and resource consumption?

- Will there be an effect on quality?

Business process mapping is one of the best ways to outline everything. You can use a swim lane diagram or a flowchart to help visualize the steps in your business procedures. Taking this approach will help you dig deep into every phase. This way, you won’t miss any steps no matter how small they may seem.

By mapping out your process, you will also uncover the source of problems. Breaking down everything will help you understand issues and identify the people responsible for them. You can reach out to them to gain their perspective. Along the way, you can get their ideas on what they think should be done to improve the process.

Step 3: Get Upper-Level Support

According to the same BP Trends report, one of the biggest obstacles in executing a business process improvement plan is getting senior management approval. 48% of respondents say that upper management is simply not interested or has its focus elsewhere.

As such, it is important for you to get buy-in from the bosses.

Remember that improvements consume resources and time. Without senior management commitment, you won’t be able to proceed with your plans. So, once you’ve analyzed process issues, make sure you thoroughly discuss the improvement project with the executives.

Step 4: Create an Improvement Plan

In this step, you’re going to redesign the problematic part of your business process. You need to come up with an improvement plan that will add efficiency to operations. As we’ve mentioned, you should discuss this with the people involved in the particular process. We also recommend using the information you’ve learned from mapping the procedures.

Also, make sure you brainstorm with everyone involved and listen to their suggestions. You need to explore ideas to ensure that you’ve got all the solutions covered. Once you’ve done that, narrow down your options to identify practical and realistic steps. This would be a great time to conduct a business impact analysis. This approach will help you identify potential failure points and risks. What’s more, it will let you comprehend the consequences of the plan you’re building.

After you and the group have come up with an achievable solution, you will create a new diagram that will document all the steps.

Step 5: List the Necessary Resources

The next step is to identify the resources you’ll need to execute your improvement plan. Once you’ve done that, you need to get approval from the proper channels. A good way to justify the resources you’ll use is by preparing a business case. According to an article featured by James Cook University, creating this document will help your organization understand the cost of project options.

Step 6: Execute the Improvement Plan

Here, you may change existing teams, systems, and processes. Make sure that you treat this like a big project. After all, you will allocate resources and time while considering the risks and assembling a team to fulfill all the tasks.

Step 7: Review the Improvements

You always need to monitor the progress of the improvements you’ve made. This way, you can ensure that you’re meeting all the milestones. If any issue comes up, you must be ready to make proper adjustments.

Also, always communicate with your team throughout the project. Ask for their input to know how the new process is faring. You should know if they find anything frustrating or confusing. This way, you’ll have the necessary information for tweaking the process. As a result, you’re making valuable improvements instead of useless changes.

The Benefits of Improving Business Processes

We’ve already discussed the importance of business process improvement. However, you also need to know its benefits to understand the value it can bring. Here are the things you can expect when you invest in business process improvement:

Optimized Work Due to Automation

McKinsey’s research says that 45% of activities performed by paid individuals can be automated through proper technology. It further explains that while this can be fully done on less than 5% of occupations, about 60% can have 30% of their activities automated.

With the right methodology, technology, and skills, you can boost efficiency and increase productivity. Business process improvement can also enhance the quality of work by getting rid of tedious or repetitive activities.

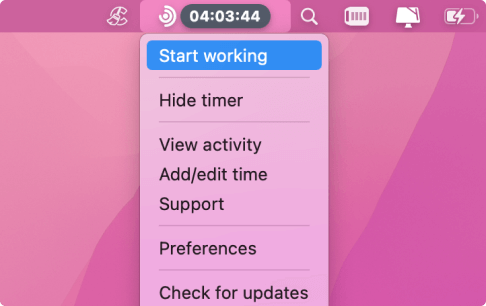

There are many ways you can use technology to improve business processes. For instance, instead of instructing employees to manually create timesheets, you can use a time tracking app like Traqq. This tool will simplify the entire invoicing process by logging work hours automatically. All employees have to do is click Start and the app will generate daily, weekly, and monthly timesheet reports.

By eliminating the repetitive and time-consuming task of manual timekeeping, Traqq can help streamline your business operations and boost productivity. So, make sure you include Traqq in your business process improvement plans today.

Better Customer Experience and Satisfaction

The more you interact with your customers, the better their experience will be. You may consider sending thank-you notes or asking them how your service was. However, these activities can be challenging to conduct if you’re doing them manually.

As we’ve mentioned, part of business process improvement plans is applying automation. You can initiate a new workflow by using trigger events like a visit to your website page, a purchase, or webinar attendance. When there’s a high level of accuracy and consistency, you can build trust with your customers. You can even get them to influence their friends and family to use your service or product.

Optimized Business Costs

Business process improvement involves a comprehensive analysis of your company’s budget, figures, and pain points. As a result, you can identify unnecessary expenses and save money. In a Harvard Business Review article, business experts shared some ways business process improvement decreases costs:

- Consolidating incidentals

- Taking overdue personnel activities

- Reducing department management spending

- Gaining control of miscellaneous expenses

- Managing pay increases reasonably

- Recycling rejected cost-saving solutions

- Eliminating any work that costs more than its value

Lowered Risk

When things are done manually, there’s a higher risk of human error. Whether you’re writing an invoice or adding thousands of products, you may make mistakes in calculations, data entry, or information transfer. No matter how robust your manual system may be, human errors are unavoidable.

By putting process improvements and automation in place, you can avoid these issues. Where humans may struggle, a system can take care of things and reduce the chance of mistakes.

Stronger Employee Morale

Many business process improvement methodologies include employees. After all, they are the driving force behind the success of a company.

According to SHRM’s 2016 Employee Job Satisfaction and Engagement report, 50% of employees consider a healthy work environment as an important factor in job satisfaction.

Now, if the processes in place are too complicated, workers will not be motivated to be productive. By improving your operations, you can streamline workflows in favor of your employees. When they are happy, they are willing to achieve more. As such, you’ll boost productivity while lowering your turnover rate.