Any company that wants to remain competitive in the business world must strive to improve its operational efficiency.

In a recent study published by PWC, CEOs were asked which activities they were planning in the next 12 months to drive revenue growth. 77 percent cited operational efficiency.

This shows that whether you deal in marketing, consulting, legal, or training services, focusing on operational efficiency will help improve your financial standing.

Even if your team is currently meeting its goals (sales, growth, etc.), there are always ways to increase output and reduce input.

Though improved profits are desired, they aren’t the accurate indicator of better-operating efficiency, nor is a larger personnel base.

Keep reading to find out everything you need to know about operational efficiency, its importance, and strategies to improve operations.

What Is Operational Efficiency?

Operational efficiency is a metric used to compare an organization’s inputs and outputs.

Inputs entail resources like people, money, machinery, inventory, and time, while outputs are the deliverables you expect from a project.

Operational efficiency is all about creating a leaner, agile, and more profitable enterprise, while still delivering high-quality services or products.

When a company maintains high operating efficiency, it gains a competitive advantage and increases profits.

Additionally, it satisfies customer expectations and improves its internal operations to handle rising demands.

Ultimately, your focus should be to obtain more output from a limited input. The higher the efficiency, the lower the costs to generate the same or greater income.

To achieve enhanced efficiency, you must understand how to plan and allocate the resources you have in a manner that fulfills your company’s goals better.

Operational Productivity Vs. Efficiency: What’s the Difference?

Often, people use the terms “operational productivity” and “operational efficiency” interchangeably. However, they mean different things.

According to an article in the Harvard Business Review, Michael Mankins summarizes it nicely: “Efficiency is about doing the same with less, and productivity is about doing more with the same.”

For a business, productivity is closely related to performance, while efficiency is minimizing inputs to boost productivity.

When the administration is trying to improve productivity, they are essentially investing the current resources to generate more output.

For a manufacturing company, improving productivity would mean finding ways the same number of employees could create more products without working extra hours.

Operational efficiency would mean having fewer employees make the same number of products using the same amount of time.

How to Calculate Operational Efficiency

We now know that operational efficiency is concerned with the inputs and outputs of your business. But how do you measure it? By creating key performance indicators (KPIs) and establishing prime targets.

Once you achieve these targets, you set new ones and work towards accomplishing them. It’s this continuous improvement and achievement cycle that keeps teams motivated.

But to master the fundamentals of operational efficiency, you must understand how it’s calculated.

First, you must create a baseline of operations which entails all the activities, operations, and functions that help run the organization.

A good approach is to hold one-on-one sessions with department heads to learn what they need to reach departmental goals.

You then combine everything you’ve learned to create an operational baseline. Some of the items you can discuss include:

- The purpose of the department, team, or individual employees within the organization.

- How the department contributes to helping the company reach its goals.

- What are the department’s primary roles and responsibilities?

- What resources are available to carry out those roles?

Once you’ve established a clear baseline, use this simple method to calculate the operational efficiency of your business:

Operational Efficiency = Operating Expenses / Total Revenue

Here’s an example: Your business earned a revenue of $200,000 in the past year. You incurred a total of $50,000 in operational expenses to achieve the profit.

Using the formula above, the operational efficiency would be 0.25 or 25 percent.

Now, let’s assume the following year your revenue bounced to $280,000, but you managed to decrease your operating expense to $35,000. Your operational efficiency would then be 0.13 or 13 percent.

From this example, it’s clear that generating the same or higher profits while focusing on cost-effectiveness reduces your operating efficiency.

Why Measure Operational Efficiency?

To quote management guru Peter Drucker, “What’s measured, improves.”

If you’ve never measured your company’s performance, it’s unlikely you have any idea how much inefficiency has built up. In a competitive marketplace, this can be a costly mistake that can lead to falling behind your competitors.

We mentioned earlier that the best approach to measure your company’s operational efficiency is to outline KPIs. This will help you establish whether or not you’re meeting your goals.

Continuously measuring the company’s performance as well as that of your teams enables you to evaluate your resources and earnings. You can then compare this to industry averages.

Knowing where you stand can help you define new, clear, and measurable objectives that will steer your company forward.

You’ll learn what was lacking in the previous processes that prevented you from achieving your goals. You can then create S.M.A.R.T goals to maximize your operational efficiency.

In the process of measuring the current operational efficiency level, you may notice some employees’ strengths in handling specific tasks or resources.

You can then use this data to assign the right tasks to the right professionals, in an effort to maximize efficiency.

In the long run, you’ll attain a high return on investment (ROI) at a reduced operational efficiency rate.

What’s the Importance of Operational Efficiency?

Every business regardless of its size can benefit from being more efficient. To do so, you must embrace reviewing your business every day and seeking opportunities to do things better, smarter, and more efficiently.

Apart from increasing profits, operational efficiency can:

Help Eliminate Waste

A study by Voucher Cloud indicates that the average worker is only productive for merely two hours and 53 minutes each workday.

This means that employees are generally unproductive for five hours and 37 minutes, assuming they work eight hours a day.

Developing operational efficiency strategies allow you to limit or cut the amount of time spent by workers on inefficient or non-value-added processes.

When you maximize the amount of value-added activities, you’re on the right path to making your business more competitive and profitable.

Help Streamline Processes

According to Asana’s Anatomy of Work Index, 60 percent of the time is spent on “work about work”. These are all the activities you do throughout a workday that don’t contribute to meaningful work.

Work about work can waste one of the most precious resources in a business – time. Minimizing these activities enables employees to get more time on their hands to do what they were actually hired to do.

It will mean more focus on work and hence improved efficiency and productivity.

Identify and Fix Problems

Another goal of operating efficiency is to identify problems so you can formulate solutions. For example, if service provision is lacking, your customers may start complaining of poor quality of services.

Since hiring can be expensive, the better option is to train your existing employees to empower them to offer services in the best way possible.

By improving your current resources (workforce), your customers will be happier, and profits will be greater.

Increased Profits and Revenue

When you eliminate waste, reduce repetitive tasks, and satisfy customers, you’ll well be on your way to greater profits. Operational efficiency helps you solve production problems and improve quality while cutting costs.

If done properly, it can result in a dramatic increase in your bottom line.

Changing the way your business operates can also:

- Give you a better understanding of your business goals

- Offer better insights to help you meet business challenges

- Enable you to establish and implement employee engagement strategies that actually work

How to Improve Your Organization’s Operational Efficiency

Now that you understand what operational efficiency is and why your business needs it, it’s time to put it into use. If you’re wondering where to start, don’t fret.

We’ve outlined six key operational efficiency practices to employ, so you can reign in on declining profits, revenue losses, and difficulty meeting demand.

1. Analyze the Current Business Situation

First, you need to take a critical look at your company’s current state. That means starting from the ground up and assessing everything that’s going on in the business right now. Some of the main areas to consider include:

- reviewing your financial performance

- understanding your employees’ productivity ratio and benchmarking against the market and competitors

- reviewing your baseline of operations to understand the business goals, strategies functions, values, policies, organizational structure, workflows, and processes

- scrutinizing your operations to identify sources of waste, such as transport, unnecessary operations, unnecessary employee movements, and overproduction

- reviewing historical data to identify which work solutions are effective and which ones need changing

Studying the current process flow will help business leaders evaluate the condition of the organization in the market in which it operates. Don’t just focus on problem areas, but the whole situation of the business.

You want to get a good understanding of the entire business operations, so you can get to the root cause and offer long-term solutions.

2. Conduct a Root Cause and Cost Center Analysis

This step involves categorizing and prioritizing a list of all the costs and expenses. Take an in-depth look at which expenses are necessary for your business operations and utilize the 5 Why’s Analysis to quickly get to the root of your problems.

You can then identify which costs are inefficiencies that could be hurting your bottom line. Identifying failures isn’t enough if you don’t know where they are coming from.

Plus, knowing the origin of a problem saves you from creating band-aid solutions that only mask inefficiencies for the short term.

3. Develop an Action Plan

Once you’ve identified inefficiencies in your business operations and categorized them, you need to create a list of solutions to address those issues.

The action plan details the milestones to track progress, a timeline for completion, and the task force to steer this initiative.

For effective application of solutions, experts advise dividing the solutions into two groups:

- Short term: those that can be completed within the next four to six weeks. These solutions are best assigned to senior management, who have the independence and authority to make impactful decisions.

- Long term: those that have a deadline of up to 12 weeks to be completed. These entail enterprise-level changes that can impact several departments in your company. Be sure to involve all the stakeholders who might be affected by the changes and empower them to implement these recommendations.

4. Implementing Change

Employees tend to resist change mostly because they fear the unknown or are concerned about their ability to perform new roles. So, before you introduce any changes, explain your intentions and what they should expect from the changes.

Outline details about the problems and how the changes will resolve them. Failure to educate your staff on why the changes are being implemented and how it’s important to them makes it harder to get team buy-in.

You should also involve your teams in the action plans, so they can partake in the decision-making processes that affect them.

This way, teams will already be familiar with what’s going on and more willing to participate in the process.

Once teams accept the changes and implementation is successful, do regular follow-ups to track progress and impact. This way, you’ll identify challenges and bottlenecks, and discuss the best way to resolve them.

Keep in mind that processes can be refined or adjusted for better adaptability. Just remember to update teams on any changes you make, even as you monitor their participation.

5. Eliminate Issues with Automation

Performing this entire process manually will not only take a much longer time, but it can be prone to human errors. Automation is the secret to enhancing your operations in today’s hyper-competitive marketplace.

One survey concluded that U.S businesses waste $1.8 trillion every year because of repetitive tasks.

Automating processes instantly reduces errors and takes over the tedious repetitive work. In turn, employers and employees will have more time to tackle value-added tasks.

Automation also enables you to create standardized processes using software to streamline workflows. This dramatically reduces the time it takes to deliver results.

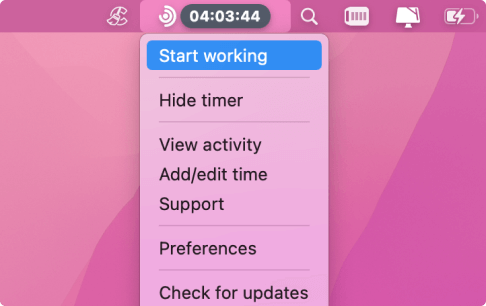

Another area you’d want to look into keenly is your time management strategies. To effectively improve the operational efficiency of your workers, you must understand how they spend their workdays.

By leveraging digital technology, you eliminate errors and delays that might be rampant with manual processes. For example, a time tracking app will automatically capture all the hours logged by your employees.

The data can be used by the accounting team for billing purposes without wasting time waiting for employees to submit manual timesheets and rectifying mistakes.

What’s more, you can monitor your team’s workload and adjust deadlines and goals accordingly. You’ll be able to prevent burnout and set a more realistic expectation about deliverables.

By tracking time, you’ll also learn about the pattern of business (high and low seasons) and know when to outsource work.

6. Develop a Financial Strategy

The last step is to develop a financial strategy to scale your business and maintain operational efficiency. Business operations rely on numbers. So, when thinking about new ways to boost revenue, you must consider opportunity costs, margins, and expenses.

All these require a foolproof financial management plan. You need to be in a position to make better business decisions without going over budget.

Operational Efficiency FAQs

Q: What is operational performance?

A: Operational performance refers to the measurable aspects of the outcomes of a company’s processes, which are combined to accomplish greater output. It involves all departments of an organization working together to achieve core business goals.

Q: What are examples of operational efficiency?

A: The following are common examples of operational efficiencies:

- Energy efficiency

- Equipment efficiency

- Marketing efficiency

- Process efficiency

- Energy efficiency

Q: What is operational efficiency in an organization?

A: Operational efficiency is the ratio of your organization’s inputs (time, money, people, equipment) to outputs (deliverables, revenue). It’s the ability to deliver high-quality goods and services with minimal waste or in the most efficient manner.

Q: Why is operational efficiency important?

A: Operating efficiency serves a crucial role in any business. Some of its benefits include:

- Eliminating waste

- Reduced costs

- Satisfied customers and happier employees

- Increased profits

- Highlighting bottlenecks within your processes so you can devise ways to fix them

Q: How do you calculate operational efficiency?

A: Here’s the formula to calculate your organization’s operational efficiency:

Operational Efficiency = Total Operating Expenses / Total Revenue

You can multiply your answer by 100 to get the operational efficiency percentage.

Wrapping Up

Improving your business’ financial standing starts with measuring your operational efficiency rate. You’ll need to evaluate the operational activities that generate your products and find the best approaches to reduce waste without compromising on quality.

One area you should focus on to achieve operational excellence is automation. It will transform how your company operates and streamline your processes.